We express our sincere congratulations to the Tengiz SLB team, M-I SWACO segment, represented by Kaz M-I JV, on their remarkable achievement of providing TCC services on Tengiz field for a 4000 days LTI free.

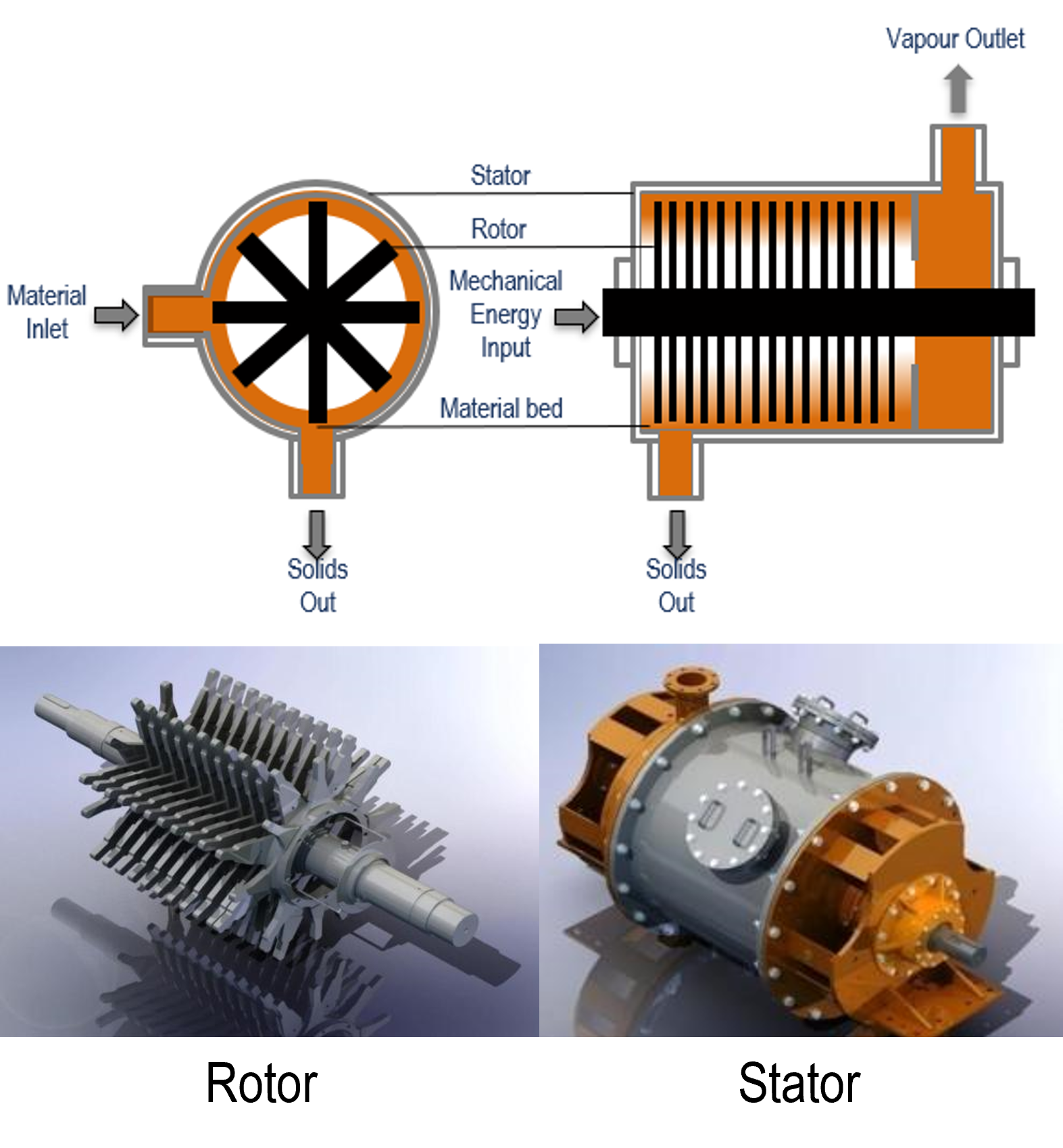

Thermo-mechanical Cutting Cleaner (furthermore – TCC) operates through the conversion of kinetic energy into thermal energy within an enclosed system.

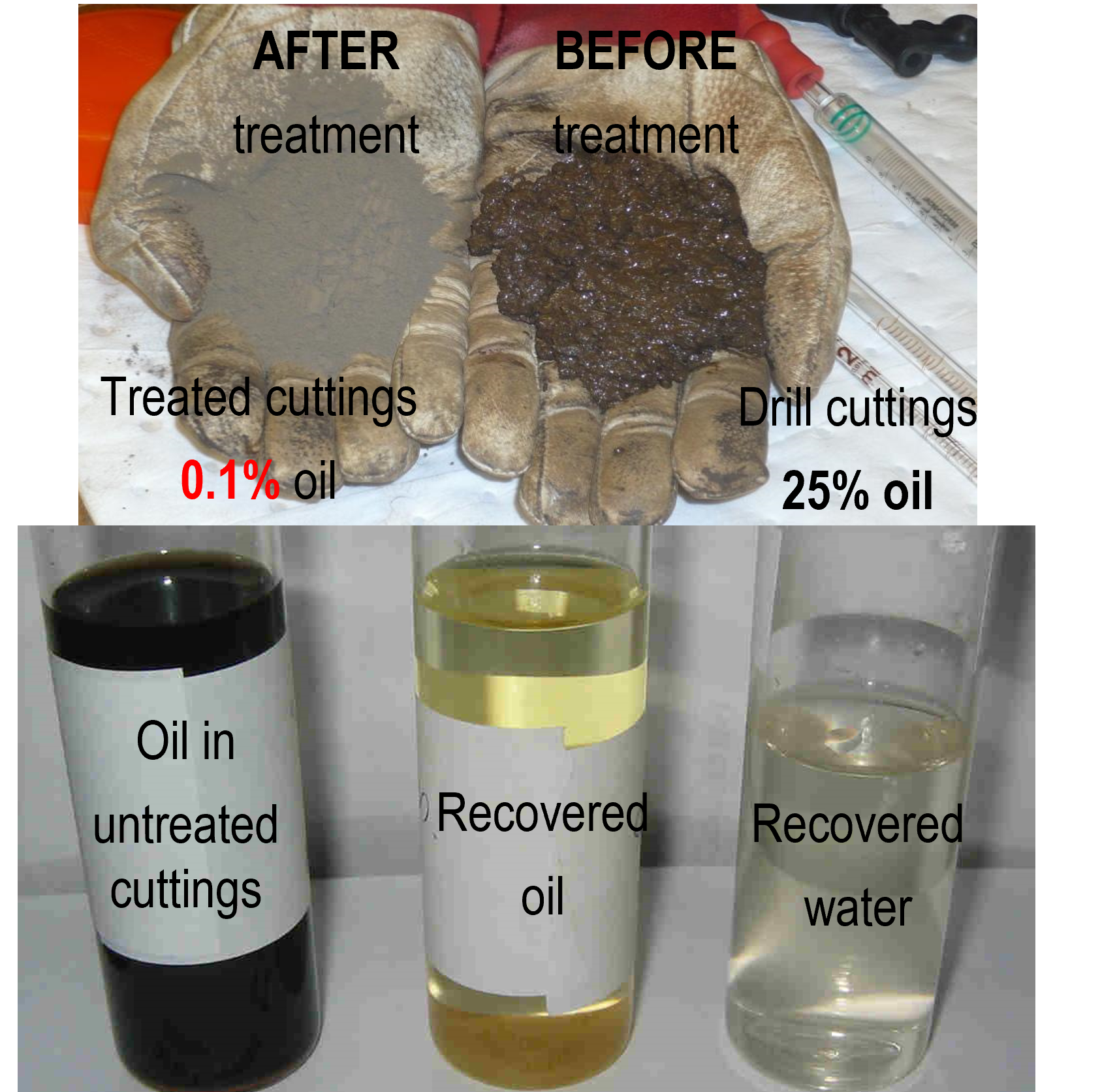

Commonly known as the TCC Hammermill, the rotor is equipped with hammers that mechanically grind oil-based drill cuttings, generating friction and temperatures of up to 300˚C. This elevated temperature facilitates the separation of water, solids, and oil. The treated solids produced by the TCC unit contain less than 1% of total petroleum hydrocarbon (TPH).

ACHIEVEMENTS:

- ZERO Lost Time Incident (LTI) since December 2013, spanning an impressive 4072 days

- Treated waste processed on Tengiz: oil slop and drill cuttings – 271 000 MT.

If we will consider treated waste from the Kashagan project (146,000 MT), the total waste treated by our team in Kazakhstan amounts to 417,000 MT.

- 25% of diesel fuel (by volume) has been recovered – 214’405 bbls.

Considering local diesel fuel prices, this recovery amounts to nearly $20 million US dollars.

- 15% of waste has been recovered as water - 139’523.6 bbls and reused on the field.

- 40% reduction in the overall volume of waste.

TCO (TengizChevroil) has delivered 875,434 bbls of waste to the TCC unit and took back only 521,505 bbls (353’928 bbls less).

Additional benefits:

- Reduction of trucks trips to the landfill and back on 40%

- Reduction of waste amount on 40%

- Reduction of oil content on cuttings from ≈25% to an impressive 0.1% (treated waste is almost oil-free).

Kaz M-I TCC team stands as the most experienced operational team globally, boasting 20 years’ experience. These accomplishments by the TCO and M-I SWACO (SLB company) team exemplify outstanding environmental stewardship and lean management practices.

Our team’s next objective is to reuse treated cutting and avoid (minimize) disposal of any drilling waste to the landfill (close to “zero” discharge and 100% reuse of all wastes)!