Screen Pulse

The SCREEN PULSE fluid and cuttings separator is a retrofitted, fully pneumatic operated system that creates a pulsating suction below the last screen at the discharge end of the shaker, separating the free fluid from the cuttings and generating significantly drier drill cuttings.

Efficient design and operation

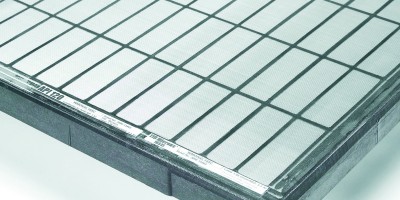

An automatic pneumatic control panel operates the SCREEN PULSE separator on up to four shakers simultaneously. The system uses a lightweight pan installed as a drop-in, within the shaker bed underneath the screen. An air valve mechanism is attached to the pan creating a gentle suction on top of the screen, pulling all the residual drilling fluid from the screens surface and the drilled cuttings as they travel toward the discharge end of the shaker. Combined with a DURAFLO composite replacement screens, this reduces waste treatment, transportation, and disposal fees. By optimizing fluid recovery, the SCREEN PULSE separator transforms what would normally be wasted into a valuable commodity.

Fully pneumatic system

The SCREEN PULSE fluid and cuttings separator is a retrofitted, fully pneumatic operated system that creates a pulsating suction below the last screen at the discharge end of the shaker, separating the free fluid from the cuttings and generating significantly drier drill cuttings.

Efficient design and operation

An automatic pneumatic control panel operates the SCREEN PULSE separator on up to four shakers simultaneously. The system uses a lightweight pan installed as a drop-in, within the shaker bed underneath the screen. An air valve mechanism is attached to the pan creating a gentle suction on top of the screen, pulling all the residual drilling fluid from the screens surface and the drilled cuttings as they travel toward the discharge end of the shaker. Combined with a DURAFLO composite replacement screens, this reduces waste treatment, transportation, and disposal fees. By optimizing fluid recovery, the SCREEN PULSE separator transforms what would normally be wasted into a valuable commodity