Filtercake Breakers

Enhance completions and reservoir producibility with effective, efficient filtercake destruction

The MUDSOLV NG integrated filtercake removal service uniformly removes the filtercake in openhole completions through the use of innovative analytical tools, engineering solutions, and novel breakers for complete removal of the most obstinate filtercake. The service tailors the best possible openhole filtercake cleanup program for each application.

Improve efficiency by optimizing the filtercake breaker

After analyzing your reservoir, well path, reservoir drill-in fluid (RDF), and completion objectives, M-I SWACO fluids experts use BREAKER ADVISOR breaker product selection software to narrow the field of potential solutions. Using samples of the RDF and reservoir rock and fluid, our laboratory specialists formulate, test, refine, and help implement the most effective solution to meet your goal and fit your bottom line.

Water-based breakers

Optimize drilling while maintaining the ability to remove the filtercake at the right time.

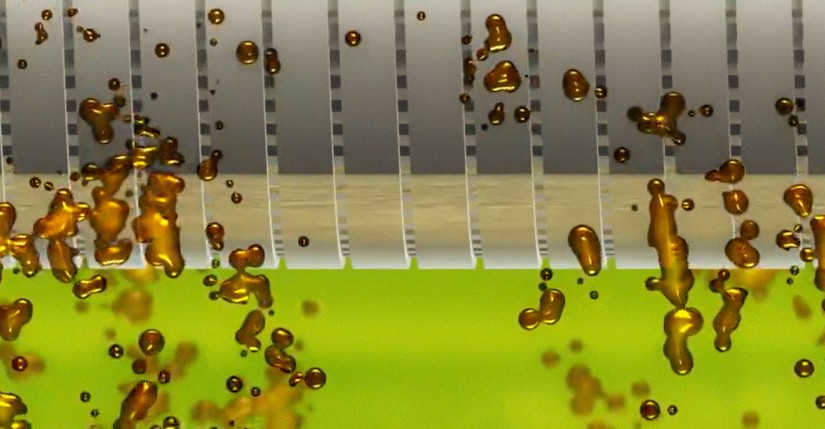

Invert-emulsion breakers

Accelerate ROP in the openhole reservoir section while maintaining the flexibility to remove the filtercake.

Internal breakers

Promote improved filtercake destruction in openhole completions, enhancing well performance.

Filtercake Breakers Offerings

D-Grade - Self-destructive bridging agent

Applications

- Self-destructive fluid loss control pills for completion or intervention operations

- Tunable, extralong-delay filtercake breaker for moderate temperatures

How it improves wells

- Offers various size options for blending

- Easily mixes into the fluid system

How it works

D-Grade self-destructive bridging agent is a versatile additive that can be used both in self-degradable fluid loss pills and filtercake breakers. With sufficient temperature, D-Grade agent reacts with the aqueous phase and dissolves itself, thereby releasing acid that will destroy nearby filtercake components and eliminate the need for postplacement cleanup. This agent is used in self-degrading fluid loss control pills to provide primary fluid loss control for a desired period of time. D-Grade agent is ground to specific sizes to act as a bridging agent. With an optimized blend of particles, fluid loss control is minimized. As a bridging solid, concentrations of D-Grade agent range from 10 to more than 70 lbm/bbl [28.5–200 kg/m3], depending on the application. D-Grade agent is available with various particle size distributions. The optimum blend of D-Grade agent sizes is determined using OPTIBRIDGE bridging agent selection software, and fluid loss is optimized in the laboratory. D-Grade agent is also used as an internal breaker in the D-Link self-dissolving fluid loss control pill at concentrations between 1 to 10 lbm/bbl [2.9 to 28.5 kg/m3]. As a filtercake breaker, the agent is used at concentrations of 15 to 100 lbm/bbl [42.8 to 285 kg/m3], depending on the breakthrough time required and composition of reservoir drill-in fluid. SAFE-VIS E liquid polymer fluid loss control additive at 0.5 to 2.0 lbm/bbl [1.4 to 5.7 kg/m3] is required to suspend solids for filtercake breaker applications. Degradation time of D-Grade agent will vary depending on the base fluid, density, and bottomhole temperature.

Limitations

- Agent degrades rapidly above 220 degF [104 degC] and may not activate below 170 degF [77 degC]

- Dissolution time is dependent on base fluid and temperature; lab testing required to confirm delay

- Corrosion inhibitor is recommended when used as a breaker

D-STRUCTOR HD - Organic acid precursor

The D-STRUCTOR HD organic acid precursor is designed for high-density breaker applications that require zinc bromide as base brine. It converts to organic acid given temperature, time, and free water. The primary function of the precursor is to slowly release organic acid through hydrolysis, which helps to minimize losses during breaker placement and to achieve uniform filtercake removal across the open hole. Due to its slow-acting nature, the breaker system can be spotted and the workstring can be extracted from the openhole section without losing fluid into the formation. If a fluid loss control device is present, the breaker system can soak for an extended period, enabling a thorough and uniform filtercake removal while maintaining completion hardware integrity. For optimal filtercake removal, use D-STRUCTOR HD precursor in concentrations of <20% by volume.

D-Lay - Breaker controlled release agent

Where it is used

D-Lay breaker controlled release agent is used as a self-degrading fluid loss control additive when fluid loss control is desired for a period of time and a fluid loss control pill is used. It is used in combination with D-Grade self-destructive bridging agent, as a component of the internal breaker or bridging package of self-degrading solids-laden or crosslinked hydroxyethyl cellulose (HEC) fluid loss control systems, to achieve required delay time above 200 degF [93 degC].

How it works

D-Lay agent is recommended for bottomhole temperatures above 200 degF [93 degC]. At these temperatures, D-Lay agent hydrolyzes and inhibits the D-GRADE agent reactivity rate to help achieve the required delay time.

What else I should know

The agent may not activate below 200 degF [93 degC]. Lab testing is required.

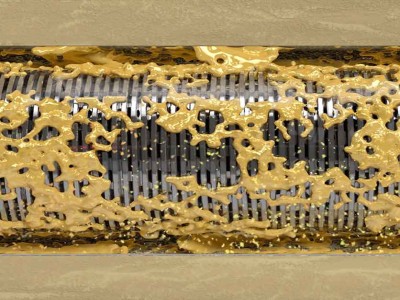

FAZE-OUT - Reversible-system water-based filtercake breaker

Expedite and simplify the openhole completion process

In either injector or producer wells, the FAZE-OUT reversible-system water-based filtercake breaker completely dissolves reversible invert-emulsion filtercakes, permitting ready injection or flowback through restrictive completions such as premium screens or openhole gravel packs. The system is used to adjust the pH and convert the filtercake of an oil- or synthetic-based reservoir-drill-in fluid (RDF) from an oil-wet to a water-wet state for easier and quicker removal. It can often eliminate preflush steps and aggressive acids, saving time and reducing risks to personnel and downhole tools.

BREAKDOWN EXTRA - Enzyme and advanced chelant filtercake breaker

Improve filtercake removal efficiency in monovalent and divalent brines

The BREAKDOWN EXTRA enzyme and advanced chelant filtercake breaker uses the D-SOLVER EXTRA advanced brine-soluble chelating agent to destroy water-based filtercakes. The agent is compatible with monovalent and divalent brines (except calcium bromide), and the corrosion rate is low as compared with acid or oxidizer treatments. The low-pH agent can complex many metal ions present in reservoir drill-in fluid (RDF) filtercakes and completion fluids, especially calcium and magnesium. The BREAKDOWN EXTRA breaker can be incorporated into a gravel pack carrier fluid if required during operations with Alternate Path gravel-pack shunt tube technology.

BREAKFREE - Enzyme-based filtercake breaker system

Maximize filtercake removal with starch-specific enzymes

BREAKFREE enzyme-based filtercake breaker system works slowly and uniformly across the lateral, providing at least 6 hours of breakthrough delay to remove filtercake from water-based reservoir drill-in fluids (RDFs). Using starch-specific enzymes, the breaker system attacks the starch fluid loss control additive that binds the filtercake. It is compatible with monovalent brines and gravel-pack fluids.

FAZEBREAK - Chelant-based filtercake breaker system

Delay invert-emulsion filtercake destruction by up to 72 hours for more uniform performance

The FAZEBREAK system uses chelant technology to reverse the wettability of reversible invert-emulsion reservoir drill-in fluid (RDF) filtercakes with unique properties that delay the breaking process for up to 72 hours. This improves uniformity of the removal process and enables placement during the completion—for example, a gravel-packing operation—to save time as compared to a separate filtercake removal operation. In addition, the system has a near-neutral pH, which reduces the corrosion rate and risks of damage to sand controls screens and other downhole systems.

SAFE-BREAK MP - Internal breaker

Expedite removal of polymer-based drilling fluid filtercake

SAFE-BREAK MP internal breaker is used to improve the efficiency of breaking filtercakes from polymer-based reservoir drill-in fluids (RDF), completion fluids, and lost-circulation pills during workover or completion operations. The breaker is initially deposited as an inert particle within the reservoir drill-in filtercake. When activated by lower pH, it greatly increases the degradation rate of the filtercake. When compared with a plain acid soak, the SAFE-BREAK MP breaker reduces the time required for filtercake removal by as much as 60%.

FAZE-AWAY - Reversible invert-emulsion filtercake breaker system

Improve flowback through premium screens and openhole gravel packs

FAZE-AWAY reversible invert-emulsion filtercake breaker system destroys the filtercake created by reversible oil- and synthetic-based reservoir drill-in fluids (RDF) to improve production through restrictive completions such as premium screens and openhole gravel packs. Unlike conventional aggressive breakers, the FAZE-AWAY system can be placed during the completion operation, such as gravel-packing, because it can delay filtercake breakthrough by more than 8 hours in most environments. This improves operational efficiency as well as uniform removal across the entire interval.

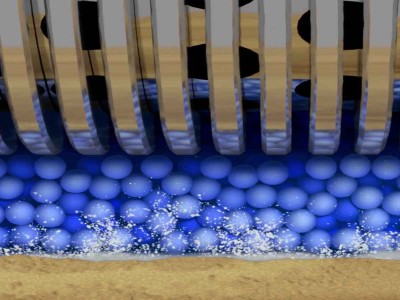

VERSA-OUT - Water-based filtercake breaker system

Optimize filtercake removal with placement during the completion

VERSA-OUT water-based filtercake breaker system allows placement during the completion operation when it is possible to make direct contact with the invert-emulsion-based filtercake, even for difficult-to-contact situations like openhole gravel packs. This improves efficiency and uniformity of the filtercake removal process, improving injection and production in openhole wells with stand-alone screens or gravel packs. The delay in breakthrough can be extended by viscosifying the breaker system. Unviscosified systems will provide about 6 hours of delay under mild conditions. Viscosifying the system can almost double the delay time under the same conditions and will increase the time required for thorough filtercake destruction.

VERSA-WAY - Invert emulsion filtercake breaker system

Optimize filtercake removal in high-temperature producer wells

VERSA-WAY invert-emulsion filtercake breaker system slowly and uniformly reacts with the filtercake created by the VERSAPRO invert-emulsion reservoir drill-in fluid system, delaying breakthrough by more than 20 hours and enabling you to pull out the service tool or washpipe without incurring losses. Designed for use in wells with temperatures greater than 200 degF [93 degC], the VERSA-WAY system is ideal for openhole completions that use stand-alone or expandable screens, and for use after openhole gravel-pack operations. The elevated viscosity of the system permits its use as a spacer or pill during displacement in openhole stand-alone applications.